This little Italian Selimco is quite hard to find and information is zero, perhaps I need a Italian private eye on my staff.

Made in a couple of colours, brown, beige or cream. Only plays 45's with large hole centres, no EP's as no speed control. In fact it's quite basic, but does have auto stop/power off. Discs are slid over silver area until fully inside and then the chrome circle spot is depressed, that then lowers the tone arm onto the record at the start position and a spring loaded tone arm is held in place and the turntable is latched. When the styli reaches the run-out area a lever underneath the tone arm catches a spinning pin on the motor controlled mini turntable that throws the arm with the help from 2 springs back to the start and releases the deck down latch.

It has a 5 transistor amp that look like OC81 type of low noise transistors. A mono crystal cartridge, Coner 33, feeds a wheel tone control and then a volume before meeting fist pre amp transistor. No diagram can be found on-line, but it's quite straight forward in design. Two printed circuit panels are used one for tone/vol wiring and the other long narrow one for the amplifier.

After it's journey from overseas the inside was a little shaken, the motor had fell from it's mounting, the crystal in the cartridge had cracked. Other troubles were eject button missing, and makers logo's gone walkies and battery door worn away and lost.

|

| Acos |

The repair

First off I decided to strip the contents from the leatherette wooden housing, this was done by some 4 BA or EU equivalents (3BA?) and 4 Philips screes and bolts, all had been glued tight, at this point I took some photos as wires were dropping off. 4 nuts held speaker to top and others were in sides. The play deck was held by 3 rotted rubber grommets and plastic push fit holding pins. I found once out the unit it could be run outside freely.

|

| Amplifier - heat sink on output transistors |

The motor wouldn't start up, so I stripped it down easily and re-oiled the bearing and washers inside, taking care not to part the bushes from the rotor arm, otherwise it would be tricky to re-attach. The motor speed control is the spinning gravity type switches, that are set at manufacture to desired speed. The advantage of this design is that when the battery voltage drops the switch contacts will compensate by speeding the motor up.

|

| Tone and volume panel and HT smoothers |

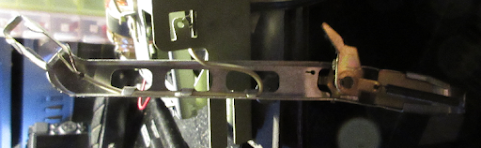

I then gently cleaned the residue from the motors spinning drive wheel (brass), then the rubber coating on the mini turntable (just big enough to engage record label) Then oil to the centre deck spindle, taking care not to get any on rubber drum or brass drive wheel. Two springs hold the motor against the drum and the hole thing privets on two rubber grommet fixings. A weak spring on the tone arm to side chassis help the return push when ejected, spring also counter acts the vinyl pulling action known as bias. This is all done crudely but effectively with tension adjustment made by bending aluminium fixing bars. I soon discovered the pick up cartridge was broken (using magnifying glass) and fitted an Acos one that was similar size, new ones were found on-line but £30+ post wasn't gonna be an option as I only paid £8 for the player, lol

|

| Main chassis, square hole for speaker magnet in lid to fold into |

The eject button was made with a small length of wooden dowel rod cut to about 1 1/2" and a rubber washer glued to top to tidy the end and in turn that was glued to a spring loaded metal bar already inside cabinet. I had an old plastic 'phonograph' badge that I fixed to the holes of the missing one, it came from a faulty remote control that I kept.

A short video of the Selimco running

No comments:

Post a Comment