Other features include negative feedback from a special secondary winding on the output transformer, provision for a gramophone pick-up and an external speaker, and a whistle filter in the output circuit.

An identical chassis is fitted in the C88 console, while the differences in the RG109, the radiogram - version, are described under "Radiogram Modifications " overleaf. This Service Sheet, therefore, covers all three models, but it was prepared from an AW88 table model.

Release date : 1937 (all models) Original prices: AW88, walnut finish £13 2s. 6d, black and ivory finish , £13 2s; 6d; C88, £16 15s; RG109, £25 14s 6d.

CIRCUIT DESCRIPTION

Aerial input, from socket A, is on MW via coupling condenser C2, and on LW via

coupling coil L2, to inductively coupled band-pass filter. Primary coils L3, L4 are tuned by C34; secondary coils L9, L.10 by . 040. On LW, aerial circuit is shunted by IF filter LI and 03. Image suppression by C39.

On television sound, referred, to as " TS", and SW bands, input is via S1 and coupling coil L5 (TS) or S2 and L8 (SW) - to single-tuned circuits L7P C40 (TS) or L8y 040 (SW). If an ordinary aerial is used, it should be connected to socket A. If a dipole is used, its leads go to the socket "A" and the unmarked socket immediately below. Socket "E" should be connected -to earth.

Tuned circuits are connected via selector switches 810 (TS), S11 (SW), 812 (MW) and 813 (LW) to CG of first valve {VU Mullen! metallised TH4A), a triode-hexode operating as frequency changer with internal coupling. Triode oscillator grid coils L11 (TS and SW), L12 (MW) and L13 (LW) are tuned by C42j parallel trimming by C43 (SW), C44(MW)' and C19 C45 (LW); series tracking by C8 (fixed—MW), C9 (fixed—LAV) and adjustable iron-dust cores in both cases. Reaction by coils Lift (TS and SW), L16 (MW) and L16 (LW).

No separate oscillator circuit is provided for the television sound band, a harmonic of the SW band serving the purpose.

the repair

Yes it had all the feel of a vintage car restoration, with bodywork needing attention and the motor needing a re-tune, lol So I've broke it all down to chapters for each jobs.

Chapter 1: the clean-up/speaker housing

It was unlikely that the woodworm were still inside the set after 83 years but I have a lot of timber in my home and I wasn't taking any chances. I quickly removed the 2 speaker baffles that held the 12" oval speaker at a strange angle, to keep most of it on the baffle I suppose. I unbolted and took the wood outside, the speaker had fell away anyway and carefully measured the weird shapes of the 2 pieces of wood so that I could make an Identical copy. by the time I'd finished it was just a pile of wood dust, and I vacuumed the rest from the Bakelite cabinet with my car vac and had to empty it 3 times.

The lower baffle fitted into a recess in the cabinet and was bolted to the main baffle so it could be laid at it 45 degree angle.

|

The new baffles - using reclaimed 3/4" plywood

|

The loudspeaker was in perfect condition, saved by the fact it had been encapsulated inside a dust bag, but even that had worm holes in it as did the speaker cloth. So new cloth was cut from a roll I brought for another Ekco I restored, so they match each other now. Don't bother to buy 'special' speaker cloth, it's too expensive and the styles don't have the gold braid so often used in early radios. I just found a cloth that looked nice and brought it on line. I did change the speaker hole shown in this photo, the hole was already in the reclaimed wood, I just squared it up so more sound could escape.

|

Brackets for quick release and speaker in place

|

Chapter 2: Is there life out/in there?

The first electrical test I made was to check the continuity of the mains transformer windings, as when this old they develop shorted turns and over heat. I got a 7 meg reading from the primary - eek!! as they say in the Beano, but the good news was it was the on-off switch causing the high reading. A small amount of switch cleaner can restore the dusty contacts, but these early types are moulded together, what to do? well what I did was to drill a 1 mm hole in the side of the housing and squirt my spay through that.

|

| 1mm hold made in on/off for cleaning access |

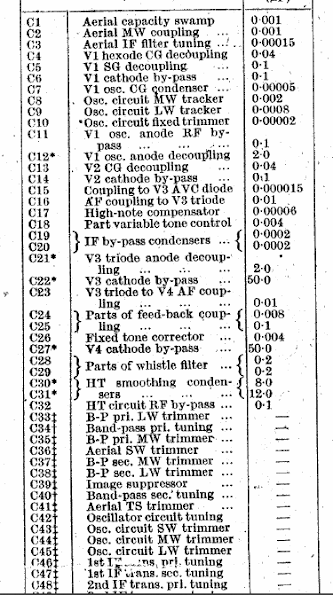

Finding another duel pot on-off from this period would be near impossible. So this was a quick fix, in the past I've taken them apart and cleaned the contacts, but they won't go back together right and can be time consuming. I cleaned the pots while there and then checked the secondary winding of the mains TX that was OK as was the heater an light bulb windings. Before I switch on I checked the main smoothers C30/31 an 8 and 12uF, because if these are O/C damage will be made to the rectifier valve and they are rarer than rockin' horse do-do, so swap them anyway. I used 2 x 22uF 450 volt working.

Chapter 3: power on

Then I switched on and was pleased to find 350 v HT rail, but no sound. I then checked the heater continuity for all the valves, and the sound output was giving me a a few K ohms when the other were just a few ohms, there was a slight cloudiness in one area of the valve that suggested that air had got in and also a small crack in the Bakelite base to the valve, this suggested the valve my have been over run. So I found a valve on-line for £9 including postage and checked all the bias components to the sound output valve and most of them were doggy.

|

Ekco AW88 circuit diagram (sound and power supply)

|

Sound output valves need a negative 'grid 1' bias b/w 5-12 volts, if this is lost the valve will overheat and destroy itself as it had done. The capacitor that feeds the anode of the previous stage with signal to the grid can leak under load and give positive volts to the GI (this is bad) so swap them anyway, I always do, they will test fine on a modern digital meter and fool you into thinking they're fine. 3 main checks on most valves is:- has it got anode and screen grid II volts and negative on grid I. Another good test is when the set's been running for a short while, switch off and with the back of your index finger feel for heat in the decoupling capacitors, especially if they are the wax type, any heat will indicate leaks and extra drain on the HT rail. I found 3 x 0.1uf (100nf) doing just that in this set. Most were screen decoupling capacitors for other valves.

|

I found a few more after I took this photo

|

Any resistor over 50K ohms needs to be checked also, early ones were not too close to the design values anyway. All this I did while I waited for my new valve to arrive, I say new it was reclaimed but seller said it was 85% good, and he was true to his word, it worked just fine.

|

Underneath showing new parts with some tropical fish capacitors

|

The big clear space in the middle is where the main smoother pack went housed in a cardboard box with wires coming out, swapping it freed up lots of access space. I replaced a few 0.004uf, used for inter-stage coupling with some 'tropical fish' types that also freed up some space. I can't see the point of fitting identical looking components as they too will be 80 years old.

|  | Left-old smoothers Right- audio TX wiring (orange, yellow, brown, red)

|

|

The speaker uses a 200 volt DC winding to power the magnet (no fixed magnet) in series with the winding is an anti-hum coil, removes mains hum pick-up. All were fine to my surprise, as most sets from this period have o/c windings and transformers, so good news for once.

|

| Ekco AW88 circuit diagram (RF section) |

I've included the full circuit, although the components are draw a little small, if you need PDF let me know. If you click the image it may go larger.

Also included is a scan of the rear, sometimes these are missing, held in place by 4 bolts to the lower frame arms and 2 bolts to the top of the set. Backs can get quite grubby, but soapy water does the trick, you may need to bend gently to reset original shape. This set didn't use a plug and socket mains lead and because of the mains transformer the chassis is isolated, but not earthed. The set needs a short length of wire for reception and especially short wave. The other band 'television sound' will be redundant now and could be used as a gram input.

Chapter 4: The tuning dial

This was hidden by dust and cobwebs, but a damp cloth soon restored it, it's hinged at the top and lifts up to reveal tuning cable an 3 x light bulbs (6.2v) 150mA, 2 were OK just one had gone, after a short while the cable broke, so I had to re-string it, a little tricky, I spent a compete morning on it. No diagram in the manual I found, so I'd drawn one out for you.

Unusually it has a spring at either end of the cables, I copied the length of the broken string, but forgot to write it down, If you guess it, you can tie knots in the cable by the springs to shorten it. The big drum is made from two wheels and if your not careful the string will fall in the gap between them (stupid design)

The tuning window had an 8" split in it that I tried to Super glue, but it kept parting. So I ordered a 1mm flexible piece of PVC (£4 with postage) similar to the Covid-19 visor types around, and laid the old one over the new piece and cut to size, the holes were a little tricky, but getting the screws back into the cabinet and through a fold bracket was subject to some bad language.

The main chassis had some rust, but not too much, so I just cleaned it up, the seller said he had an old family photo with the radio and would send me a copy, I'll add that when it turns up, it's nice to see it in it's historical context.

Chapter 5: the video

I've recently started adding a video, if you can call it that, made with a digital camera (a digeo?) I've inverted a new word, lol Pictures paint a 1000 words they say, hope so. If another one turns up (radio that is) please let me know how you get on

Chapter 6: more reading A 2006 publication by Chris Poole and Peter C Brown about the Ekco factory that goes into great detail about the social side of life and how Mr Cole was Southend's biggest employer. Not quite sure why there is a Philips radio on the front cover? perhaps he made the Bakelite front for them back in the 1930's. The presses were enormous that made them and I expect very expensive.

Special thanks to the Williams family + Bridget for the extra historical information

No comments:

Post a Comment